Splicing Fiber Optic Cable More Efficiently

The Challenge

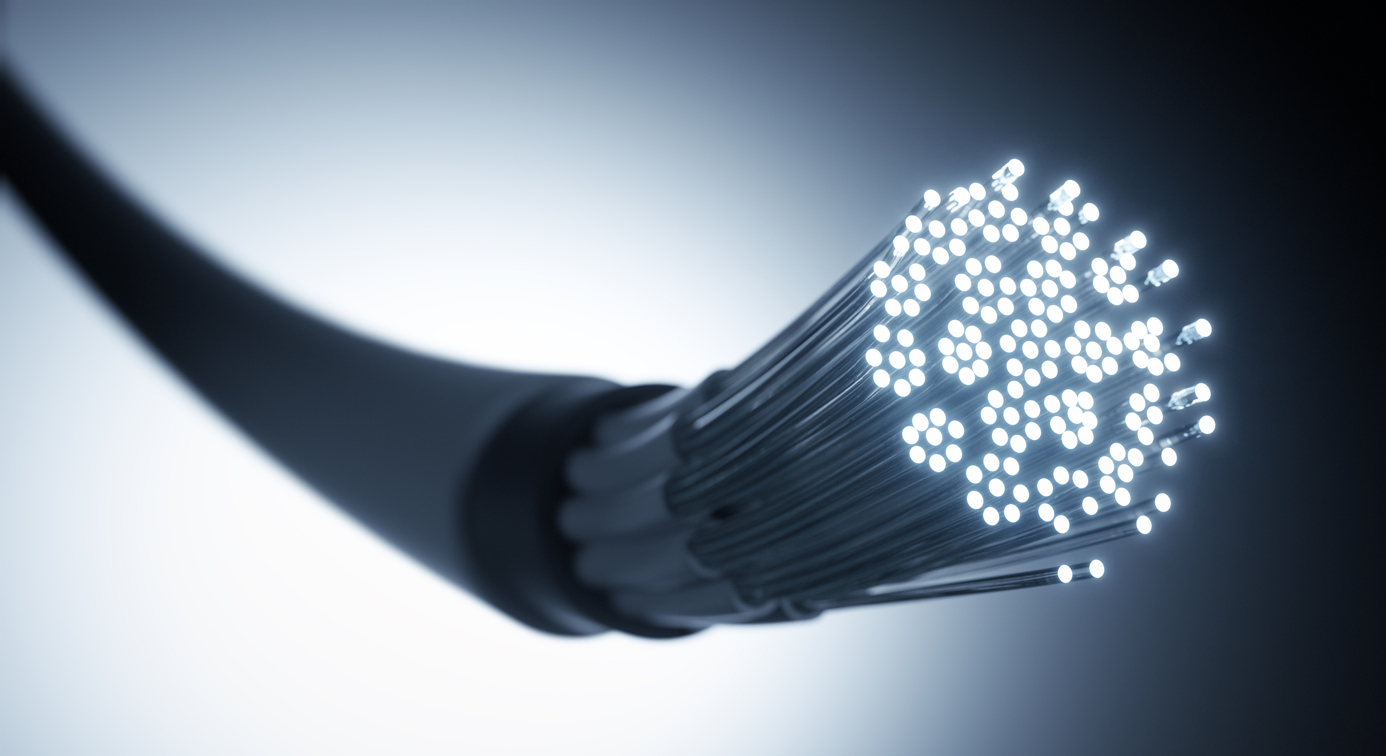

Effective telecommunication networks require perfect fiber optic cables. For Splice Technologies Inc, based in Manorville, NY, their specialty is in the high-quality fusion splice protection sleeves that shield fiber joints. Protecting the connection of two joined fiberoptic fibers is critical to ensure communication integrity. Their protection sleeves are used in some of the most punishing locations including air, space, underground and deep in the ocean. Splice Technologies describes itself as having “large company capabilities with small company quality and service”[1] with all production and services located in the United Sates. When one of their suppliers was unable to provide clean ends on their material, the team at Splice Technologies went looking for a new partner.

The most onerous and critical industries rely on their optic fiber network such as military, space, oil and submarine installations. For example, The Fiber Optic Association notes that the “military uses fiber [optic cables] everywhere, on bases, platforms (ships and planes), and on the battlefield because it's hard to damage, tap or jam.”[2]. At the heart of these cables are the fusion joints which are cleanly connected and protected with specialty sleeves that meets each application specification using the proper material. US-based Splice Technologies was founded by fiber optic expert Robert Auteri who has decades of knowledge with this technology. Eager to find someone who could solve their product quality issue, Bob reached out to Novo Precision.

The Solution

When attacking a quality issue, being able to understand the application and technical challenges of another company is a critical and unique skill. Novo Precision has decades of experience handling and cutting a wide variety of material as well as listening and understanding their customer’s problem. The engineers quickly learned that when it came to cutting material for Splice Technologies, the traditional methods of cleaning up the material edges was both ineffective and cost prohibitive. Undeterred, the engineering team was determined to solve the problem in collaboration with Splice Technologies.

The solution came in the form of alternate materials. Novo Precision is extremely dynamic with designing, procuring and processing different forms of material for each specific application. The materials selected were more expensive – around four times more expensive - compared to previous alternatives. However, it was actually a cost savings for Splice Technologies as it required significantly less processing and actually eliminated subsequent manufacturing steps.

The Result

Novo Precision was able to step in and solve a part quality issue by innovating with Splice Technologies. By selecting an alternative material that still had high performance and eliminating a processing step, Novo increased quality, decreased contamination risk and decreased part cost. The overall cost savings ranged from 20%-30% across each component.

While cost is important, Bob Auteri is clear that quality is the first priority. In the fiber optic industry “[s]plices create a permanent joint between two fibers, so its use is limited to places where cables are not expected to be available for servicing in the future” [2]. Finding and accessing any failed joints is an expensive venture so perfection is required. This is why the expertise of Splice Technologies is critical and is trusted by top companies in all industries. Quality is the primary reason for Splice Technologies selecting Novo Precision. The partnership with Novo Precision and Splice Technologies was born from a technical problem and will continue forward with the foundation of quality.

The projected growth of the fiber optic market in the United States is almost 5% over the next five years, which means continued steady growth, adoption and installation of this technology.[3] Novo Precision provides scalable, US-manufactured product that will continue to grow with Splice Technologies as they continue to expand.

“As a dedicated US manufacturer, Splice Technologies seeks out partnerships with other US manufacturing experts. We also look for suppliers who have the ability to both understand our problem on a technical level and innovate with us to solve problems. This is why Splice Technologies selected Novo Precision as one of our key partners.” -Robert P Auteri, President & CEO of Splice Technologies

About Novo Precision

Novo Precision is a solutions provider. Novo offers a strong team of mechanical, manufacturing and quality engineers, as well as an on-site R&D center that greatly streamlines product launch and solution development. Novo has the capability to source materials, fabricate equipment, and engineer manufacturing processes to make your components. Or, we can create a turnkey system and train your staff to manufacture the components in your own facility. However you utilize Novo’s expertise, we provide the technology and the logistics to help you solve real world problems while you focus on your core strengths.

Novo is experiencing rapid growth as a progressive supply chain partner focused on data-driven operations, updated quality systems and improved production methods. We’ve even expanded our value streams to offer innovative products like our Lean Metrics Stand that displays daily performance metrics to allow all team members to contribute to your organization’s success.