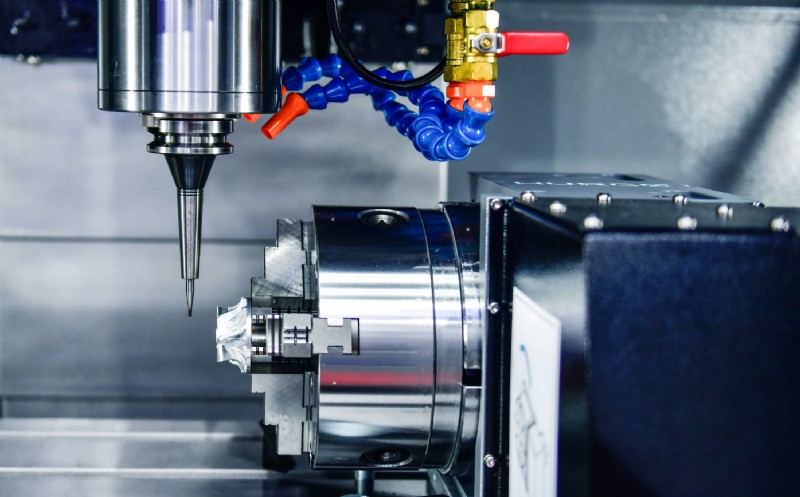

CNC-Milling Overview

At our custom manufacturing facility, we design and build machined parts for several industries all across North America. From simple brackets to more complex parts for medical and aerospace, Novo Machining specializes in manufacturing a range of custom-machined parts. Alloy steel, aluminum, brass, plastics, and composites are typical materials we work with. We purchased a new 20,000 square foot job shop and equipped it with 3- and 4- and 5 axis CNC milling machines to meet your medium to high volume production requirements. We also have in house turning, broaching and Wire EDM capabilities.

Assembly Services

In addition to Milling and Turning of parts we have in-house Assembly Lines setup to provide a full suite of Assembly Services for your products.

We are not a machine shop; we are a manufacturing partner. The investments we make in our machining capabilities are a tool that we use to solve our customer’s manufacturing and process challenges. When paired with our experienced and committed team, our CNC milling capabilities and assembly capabilities provide measurable value to our customers.

The Novo Precision mission is to simply solve our customer’s problem. We accomplish this with our cut-to-length, machining and assembly value streams using our four pillars of skills: design, build, operate and improve.

Design: We offer a strong team of mechanical, manufacturing and quality engineers, as well as an on-site R&D center that streamlines product launch and solution development. We continue to invest in engineering talent including design, manufacturing, process and engineering.

Build: We are a partner that can facilitate our customer’s proof-of-concept and prototype products. With our facilities located in Bristol, Connecticut, Novo Precision has the capability to source materials, fabricate equipment, engineer manufacturing processes and build product in-house. We support product assembly, sub-assemblies, and contract manufacturing.

Operate: We continue to be recognized as a progressive, ISO 9001:2015 certified supply chain partner focused on data-driven operations, updated quality systems and value-added production. In addition to our manufacturing skills, we provide the technology and the logistics to help solve real world problems while allowing our customer to focus on their core strengths.

Improve: Our expertise can be leveraged in any product lifecycle: from new product development, prototyping, new process development, commercialization ramp-up, mature production or end-of-life. We help our customers reduce waste in a variety of ways including improving throughput, defect reduction, value-added value engineering (VAVE) and product price variance (PPV) cost reduction.

Machine Equipment List

- Okuma Genos L250-E Lathes

- Okuma Genos M460-VE 3-axis mills

- Tsugami B0325V Swiss Machine

- Brother Speedio M200 5-axis mills

- 5C Collett Fixturing

- 5th Axis Fixturing

- Brother Speedio M500 4-axis mills

- Fanuc Robodrill D14MIA5 4-axis mills

- Sodic VL400Q wire EDM

- Programable Cutoff Saws

- Broach Cutters