Driving Down Costs & Driving Quality Up-US Manufacturing at its Finest

The Challenge

Quality. Due to ongoing quality problems from a key supplier, our customer was on the verge of losing user confidence in one of their largest product lines. Our customer manufactures an innovative chemical solution used in the service and repair of residential and commercial air handling systems, thereby saving customers from costly repairs or replacement. The product provides tremendous benefits in prolonging the service life of systems. However, problems with variable shelf life and the incidence of poor quality was negatively impacting sales and risking future growth of the product. Our customer was also experiencing exorbitant costs with 20-30% fallout due to frequent field failures, product recalls, added inspection, and rework during production, driving a very high Cost of Quality.

Addressing the problem was a significant challenge. The original supplier not only struggled with a complicated subassembly product design, but they also did not have a capable manufacturing process with problem-solving to drive improvement. Our customer was looking for stronger business partner who could help with a technical solution for the product design as well as a capable manufacturing partner to design, build, operate and improve the subassembly manufacturing process….all on a very tight timeline

The Solution

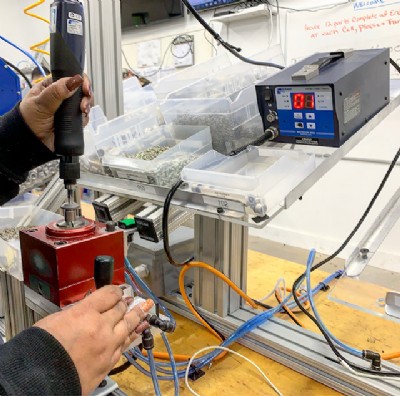

Operational expertise. Our customer was seeking a technical partner and found something that exceeded their expectations – a local manufacturing partner through Novo Precision that was able to work together to solve problems and support a rapid ramp in production. Our engineers worked closely with the customer on a redesign, we were able to understand and improve key design features to address the quality problems, as well as making the product safer. Our engineers and manufacturing team were able to design a process that 100% validated the function and the quality of a new and improved subassembly. Leveraging Process Failure Modes Analysis (PFMEA) with our customer, we assessed and mitigated quality risks before they appeared in production. As a result, the first-year returns were reduced significantly to less than 0.001%.

In addition to the technical product solution, we were able to support product manufacturing and start initial production in 6 weeks. We created a cell with lean, 1-piece process flow to efficiently manufacture the product. This also allowed for easier duplication when product demand increased. Due to our vertical integration and in-house expertise, Novo’s engineering and tool production teams were able to quickly support the manufacturing needs. We also developed the supply chain by selecting, qualifying and ramping up component suppliers which reduced the risk for future quality issues. Our project team managed each component to ensure timely delivery at every stage of production. We established a robust Quality System that yielded less than 0.001% returns in the first year. We were able to quickly ramp volumes by 1600% to meet very high seasonal customer demand.

During the second year we maintained 100% on time delivery (OTD) performance to the customer along with <0.0005% product return rate. We continue to support our customer with our focus on improving performance including perfect on-time delivery, improved cost, and first-in-class operational quality. We also continue to work closely together at multiple levels of the organization to continue to improve the product and processes.

The Result

Our customer was searching for a solution to a product quality problem and found a technical partner who had:

- Relentless focus on Quality

- Redesigned product for quality, reducing first-year returns to less than 0.001%.

- Created a strong internal quality system with over 99.9% First Pass Yield

- Uses their in-house continuous improvement expertise to improve quality

- Manufacturing capability to support the volume

- Executed from initial PO to production in 6 weeks

- Rapidly ramped production by 1600% to meet high year 1 demand

- Scaled from 1 to 3 manufacturing cells to support the step-function volume

- Supply chain foresight and process to reduce risks

- Sourced all the materials and components needed to establish a new supply chain

- Reduced cost of the product year over year

- Designed, Built, Operated, and Improved a product that is 100% sourced in USA

From a technical problem to a full manufacturing solution, the partnership with our customer is an example of how working with a world-class engineering supply chain partner can close the current product gap and prevent future quality problems.

“ Novo engineers helped us improve and simplify our product design to eliminate assembly bottlenecks and significantly improve overall product quality. We are now two years into the new design and our customers can use this product with renewed confidence that it will always function as expected. Novo has played an essential role in this product’s success, and we could not be happier with the outcome.” (Senior VP and Project Lead at Customer)

About Novo Precision

Novo Precision is a solutions provider. Novo offers a strong team of mechanical, manufacturing and quality engineers, as well as an on-site R&D center that greatly streamlines product launch and solution development. Novo has the capability to source materials, fabricate equipment, and engineer manufacturing processes to make your components. Or, we can create a turnkey system and train your staff to manufacture the components in your own facility. However you utilize Novo’s expertise, we provide the technology and the logistics to help you solve real world problems while you focus on your core strengths.

Novo is experiencing rapid growth as a progressive supply chain partner focused on data-driven operations, updated quality systems and improved production methods. We’ve even expanded our value streams to offer innovative products like our Lean Metrics Stand that displays daily performance metrics to allow all team members to contribute to your organization’s success.